Growers nowadays have various aids to help them dissolve water soluble fertilizers quickly and efficiently. Learn about common fertilizer dissolving tools, accompanied by demonstration videos

One of the most common sights on farms in the past was of a worker, or farmer, standing next to the fertilizer tank with a mixing stick in his hand, pouring fertilizer into the tank and stirring the solution. Since then, agriculture has come a long way, along with the ways and means of preparing the fertilizer solution. Some of the most popular issues in the field of soluble fertilizers is how to dissolve it quickly and efficiently, and what are the technical tools that can help the farmer with the dissolution. Here is a brief concerning the wide variety of fertilizer dissolving tools.

Eductor - Mixing Nozzle

Description: a mixing nozzle made of plastic polypropylene, resistant to fertilizer mixing environments, similar in shape and performance to a static Venturi unit.

The operating principle: the eductor connects by simply screwing it to the coupler of the water hose while filling the fertilizer tank. The special construction of the eductor (based on the Bernoulli principal) converts pressure into velocity, increases the exit velocity of the flow, leading to a better solution mix.

Recommended sizes: threading of 1/4", 3/8", 3/4", 1 1/2".

User tips: the eductor is a simple and permanent installation that actively assists in the fertilizer dissolving process as soon as water begins filling the tank, and in some other units, even up to the point when dissolving is complete. A rigid hose is recommended for installation, and it should be placed as close as possible to the bottom of the fertilizer tank in order to make the dissolving process more efficient.

Watch the demonstration video:

Air Blower

Description: Electric air blower, made of plastic polypropylene.

Supplies 1.6 HP, 1200 W at 220V, compression capability up to liquid level of 2.7 meters (manufacturer's data), and maximum flow rate of 156 cubic feet of air/hour.

Operating principle: the blower pushes hot air under pressure through the designated hose to the fertilizer tank, thus mixes and warms the solution.

Recommended sizes: in addition to the size mentioned here, there are industrial blowers, made of aluminum with similar technical spec, designed for heavy duty.

User tips: the blower is an electronic accessory with high capabilities for efficient dissolving. Its dimensions are small and it is lightweight for transporting, as well as being convenient and easy to use. It can also be installed as a permanent accessory in a shaded location that has access to electricity.

When operating, it is recommended not to fill the fertilizer tank with water up to the maximum volume since the solution could spill. At the end of the dissolving process, fill the tank to the required level. The blower has a kit compatible for dissolving fertilizer including flexible ribbed hosing, rigid PVC hosing with a divider on the end, and with suitable couplers.

Watch the demonstration video:

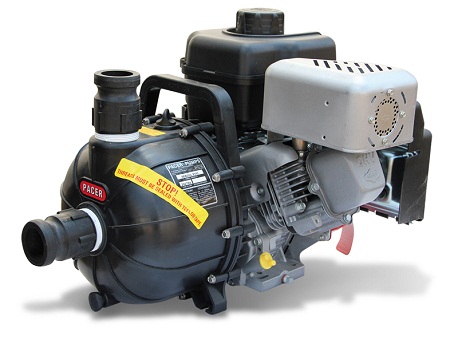

Circulation Pump - Gasoline Engine

Description: a plastic polypropylene centrifugal pump; with independent suction capabilities.

Operated by a Briggs & Stratton 5.5 HP gasoline engine, with a maximum flow rate of 800-900 liter/min.

The operating principle: the device pumps and circulates the solution from the tank and back, thus creates a mixing effect and enables proper dissolution.

Recommended sizes: entry/exit 2" - 5.5 HP engine; entry/exit 3" - 6.5 HP engine.

User tips : the pump's small size and weight turn it into an easy unit to operate in the field without electricity and with easy transportation.

Circulation Pump - Electrical Engine

Description: a plastic polypropylene centrifugal pump; with independent suction capabilities.

Operated by a one/three phase 3 HP electric engine, 2900 RPMs, with a maximum flow rate of 300-400 liter/min.

The operating principle: the device pumps and circulates the solution from the tank and back, thus creates a mixing effect and enables proper dissolution.

Recommended sizes: entry/exit 2", entry/exit 3".

The type of engine changes according to any diameter chosen by the customer.

User tips: the pump can be used for various agricultural needs in locations with access to electricity.

Watch the demonstration video:

Circulation Pump - Hydraulic Engine

Description: a centrifugal pump from plastic polypropylene or reinforced plastic and has independent suction capabilities.

Operated by hydraulic engine directly connected to a tractor or other agricultural machine with oil pressure and matching couplers; has a maximum flow rate of 800-900 liters/min.

The operating principle: the device pumps and circulates the solution from the tank and back, thus creates a mixing effect and enables proper dissolution.

Recommended sizes: entry/exit 2", entry/exit 3" - for both sizes the hydraulic couplers are identical.

User tips: the pump's small size and weight turn it into an easy unit to operate in the field without electricity and with easy transportation. It is even recommended to attach it to an agricultural tool with a permanent tank as a fertilizer distribution cart for various points in the field.

Immersion Pumps (Submersible Pump)

Description: immersed one/three phase electrical circulation pump, plastic/metal body with independent suction capability.

The pump can be used for emptying pools of water/sewage and other various farm needs. The flow rate changes according to the size of the pump and is usually between 7 to 40 cubic feet/hour.

The operating principle: the device pumps and circulates the solution from the tank and back, thus creates a mixing effect and enables proper dissolution.

Recommended sizes: exit 1" - 3" with changing flow rates.

User tips: as opposed to the external accessories described above, the immersion pump is located inside the tank and works in a fluidic environment. It is recommended to slightly raise the pump from the bottom of the tank during the dissolving process. In addition, it is worthwhile to occasionally remove it for cleaning and inspection.

Disclaimer

The information provided in this brief was generously provided by the importers.

The information is only to be considered general in nature, and is not intended to replace professional information or a technical catalogue. Any use of the information is the sole responsibility of the user. Before every use of one of the above mentioned products, the importer/marketer should be consulted and the use should be according to his/her precise instructions.

Rules of thumb for correct dissolving:

- Fill at least a third of the tank with clean water before adding the fertilizer.

- The fertilizer bags should be gradually poured into the tank while continuing to fill it with water and operating the dissolution device.

- Make sure that the fertilizer composition and concentration is correct. It is recommended to consult with Haifa's agronomists for further planning of the fertilization program.

- Make sure that the fertilizer has fully dissolved prior to injecting and dosing into the irrigation system.

- In winter, it is recommended to dilute the fertilizer solution by 20% and repeat the dissolving action with suitable equipment every two weeks.

- It is recommended to empty and rinse the fertilizer tank between seasons or prior to using fertilizer with limited chemical compatibility.